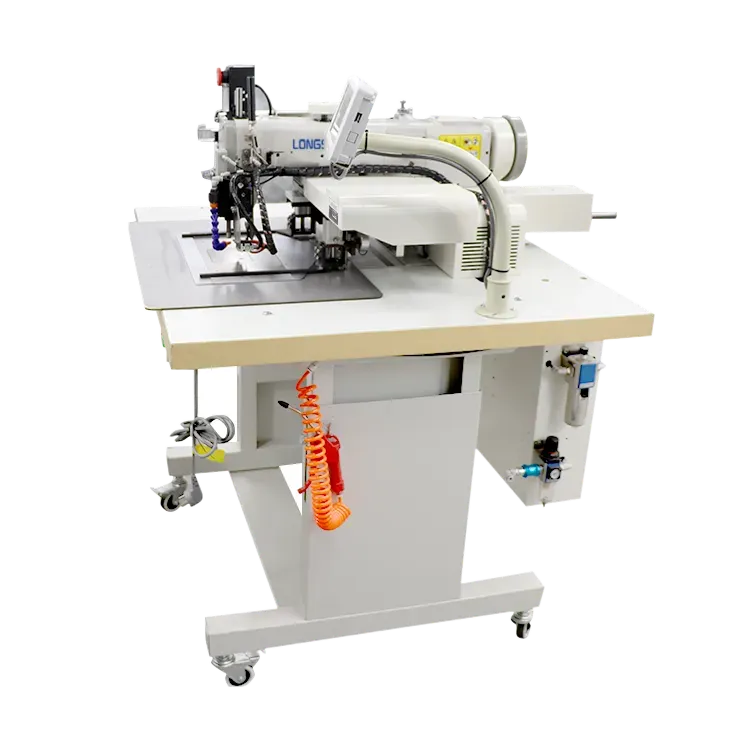

Sling sewing machine

Latest articles

Sling sewing machine1. Increased Efficiency The ability to sew through thick materials without jamming or breaking needles significantly increases productivity. Heavy duty motors enable seamstresses to complete projects quicker and with more confidence in the machine's performance.

...

Sling sewing machine 【Sling sewing machine】

Read MoreIndustrial sewing machines for leather also come with a variety of accessories and attachments to enhance performance. From edge guides to stitch regulators, these tools help users achieve precise and consistent stitching results. Additionally, many machines are equipped with automated features like thread trimmers and needle positioners, further streamlining the sewing process.

Sling sewing machine...

Sling sewing machine 【Sling sewing machine】

Read MoreSling sewing machine

...

Sling sewing machine 【Sling sewing machine】

Read More

Sling sewing machineAdditionally, using hand sewing machines can often lead to more durable and quality finishes. While mass-produced furniture may rely on automated processes that compromise craftsmanship, hand-sewn upholstery demonstrates a commitment to quality and artistry. Customers are increasingly drawn to pieces that reflect individuality and skill, making manual techniques more relevant than ever.

...

Sling sewing machine 【Sling sewing machine】

Read MoreWhether you are a professional leatherworker or a hobbyist looking to create your own unique designs, having the right sewing machine can make all the difference in the quality of your finished products. So if you are in the market for a new machine, be sure to look for one that is specifically designed for sewing leather bags. Your bags will thank you for it!

Sling sewing machine...

Sling sewing machine 【Sling sewing machine】

Read More

Sling sewing machineIn the world of textile and garment production, the double needle sewing machine stands as a pivotal innovation that has transformed the way garments are constructed. This machine is a specialized sewing tool that utilizes two needles working simultaneously to create parallel rows of stitching. It is particularly renowned for its efficiency and precision, making it a favorite in both industrial and home sewing environments.

...

Sling sewing machine 【Sling sewing machine】

Read More

Sling sewing machineIn conclusion, the lock stitch sewing machine needle is a fundamental component that can make or break a sewing project. By understanding the various sizes, types, and materials available, as well as committing to regular maintenance, sewers can enhance their skills and enjoy a seamless sewing experience. Whether crafting garments, home décor, or accessories, the right lock stitch needle can make all the difference in achieving professional-quality results. Investing time in selecting and caring for this indispensable tool is essential for anyone serious about the art of sewing.

...

Sling sewing machine 【Sling sewing machine】

Read More

Sling sewing machineIn industrial settings, single needle lockstitch machines are often the backbone of assembly lines. Their speed and ability to perform consistent stitches make them ideal for high-volume production. Many manufacturers also utilize specialized attachments and presser feet that cater to specific tasks, such as hemming or sewing zippers, thus expanding the machine's capabilities and efficiency.

...

Sling sewing machine 【Sling sewing machine】

Read More

...

Sling sewing machine 【Sling sewing machine】

Read More

Popular articles

Final Tips

In conclusion, the double needle is a powerful tool in the arsenal of any serious sewist. It combines practicality with artistry, allowing users to create beautiful, professional-quality finishes that are both functional and stylish. Whether you are a seasoned professional or a passionate hobbyist, incorporating a double needle into your sewing repertoire can open up a world of creative possibilities. As sewing continues to evolve with trends in fashion and technology, the double needle remains a timeless tool, empowering sewists to bring their visions to life with precision and flair.

Using a twin needle can drastically elevate the quality of your sewing projects. By carefully selecting your needle, prepping your machine, and practicing your technique, you can achieve beautifully finished garments that look store-bought. Happy sewing!

Handheld Sewing Machine vs. Heavy Duty Sewing Machine: Choosing the Best Sewing Machine for Beginners

Latest articles

-

2. Install the double needle Before installing the double needle, make sure to check that your sewing machine is compatible with double needles. Most modern sewing machines can accommodate double needles, but it's always good to double-check the user manual. Once you've confirmed compatibility, follow these steps to install the double needle

-

In conclusion, a seaming machine is a versatile and essential tool for anyone working with textiles. Whether you are a professional seamstress in a garment factory or a hobbyist working on DIY projects at home, a seaming machine can help you achieve professional-looking results in less time. With the right machine and a bit of practice, you can create beautiful and durable seams on a wide range of fabrics and projects.

-

The dysregulation of GSC367TD has been linked to a variety of diseases, including cancer and developmental disorders. In cancer, abnormal expression of GSC367TD can lead to the uncontrolled growth of cells, contributing to tumor formation. In developmental disorders, mutations in the gene encoding GSC367TD can disrupt normal patterns of gene expression, leading to malformations and other abnormalities.

-

4. Cotton-Polyester Blends For those who prefer a more traditional look with some stretch, cotton-polyester blends can be a good option. These blends provide a balance of strength and aesthetics, making them suitable for various crafting projects.

-

Modern industrial leather sewing machines are equipped with specialized features such as walking feet, which help move the thick material smoothly through the machine. They also typically possess a powerful motor capable of stitching through multiple layers of leather without skipping stitches. This evolution has made it possible for manufacturers to produce leather goods more efficiently while maintaining high standards of quality.

-

Finding Compound Feed Sewing Machines for Sale

Links

- Imagine stumbling upon this small metal box in an antique shop, its rusted latch barely holding on. As you open it, the hinges creaking in protest, you find a collection of old photographs, faded letters, and trinkets from a bygone era. Each item tells a story, offering a glimpse into the lives of those who once owned them. Perhaps this box belonged to a young couple in love, their memories carefully preserved within its walls. Or maybe it belonged to a soldier, carrying tokens of home with him through the trials of war.

- Another advantage of a steel security safe lock box is its strong locking mechanism. Most safes come with a variety of locking options, including key locks, combination locks, and electronic locks. These locks are designed to be tamper-proof and provide an added layer of security to your valuables.

What are aluminum profiles?

- In addition to their aesthetic appeal and durability, cast iron panels are also relatively low maintenance

- Purpose of Mosquito Net Aluminium Profile

Most of these features, which used to be unique to iron, are now available in steel, which is by a large margin the superior material. And visually, the only difference between the two is the texture. Steel is smooth, while iron has a visible grain, whether it is produced by casting, or by pulling. This grain is actually caused by impurities in the iron and is what accounts for its unreliable nature. These impurities cause weak points in the iron that can lead to breakage when it’s put under stress. Steel’s smooth appearance results from the fact that these impurities have been burned out, or, in the case of carbon, evenly distributed throughout the material. When you think of the medieval blacksmith hammering away, what he is doing is distributing the carbon evenly to turn iron into steel.

In addition to repairs, wrought iron welding near me can also be used for custom fabrication projects. This could include creating custom gates, fences, railings, or other decorative elements made from wrought iron. A reputable welding service will work closely with you to design and create the perfect piece to complement your home or business.

If you do not see signs of rust on your iron fence, or after you have removed all the rust after initially spotting it, it is ideal to apply a coat of wax to the fence exterior. This will create a protective sealant that will help prevent oxidation from occurring in the future, saving you time and money in the long run.

Repairing Screen Door Rollers A Step-by-Step Guide

The tradition of using wrought iron in decorative fencing dates back to the Roman Empire, where blacksmiths forged iron into both functional and ornamental pieces. By the Middle Ages, wrought iron became widely used in Europe for gates, railings, and fences, often adorned with intricate designs that showcased the skills of the blacksmith. Each piece was unique, reflecting the style of the period and the individuality of the homeowner. This practice has continued through to modern times, where wrought iron fence ornaments are still handcrafted, blending traditional techniques with contemporary designs.

Anodizing increases the natural oxide layer on the aluminium, while powder coating adds a durable, color-fast finish Anodizing increases the natural oxide layer on the aluminium, while powder coating adds a durable, color-fast finish

Anodizing increases the natural oxide layer on the aluminium, while powder coating adds a durable, color-fast finish Anodizing increases the natural oxide layer on the aluminium, while powder coating adds a durable, color-fast finish aluminium window profile manufacturers. Some manufacturers also offer thermal break technology, where a non-conductive material is inserted between the inside and outside sections of the profile to improve insulation and reduce heat transfer.

aluminium window profile manufacturers. Some manufacturers also offer thermal break technology, where a non-conductive material is inserted between the inside and outside sections of the profile to improve insulation and reduce heat transfer. The procedure may differ slightly based on the door model, but generally, it includes unscrewing the roller assembly from the door frame, detaching the old roller, and attaching the new one in its place The procedure may differ slightly based on the door model, but generally, it includes unscrewing the roller assembly from the door frame, detaching the old roller, and attaching the new one in its place

The procedure may differ slightly based on the door model, but generally, it includes unscrewing the roller assembly from the door frame, detaching the old roller, and attaching the new one in its place The procedure may differ slightly based on the door model, but generally, it includes unscrewing the roller assembly from the door frame, detaching the old roller, and attaching the new one in its place aluminium sliding door roller replacement. Make sure to follow the manufacturer's instructions carefully to avoid damaging the door or the new roller.

aluminium sliding door roller replacement. Make sure to follow the manufacturer's instructions carefully to avoid damaging the door or the new roller.Quality:

Installing heavy duty sliding door rollers is a relatively simple process that can be done by a professional or experienced DIYer. By following the manufacturer's instructions and ensuring proper alignment and lubrication, you can ensure smooth and trouble-free operation of your sliding doors for years to come.

7 Items to Consider When Buying Wrought Iron Fence and Gates

Cast iron is known for its strength and resistance to wear and tear, making it an excellent choice for outdoor applications. Unlike wooden fences that can rot, warp, or be eaten by pests, cast iron requires minimal maintenance over the years. It can withstand harsh weather conditions, including rain, snow, and ultraviolet rays, without deteriorating. Even if the paint chips, the underlying metal remains intact, allowing for easy touch-ups that can restore its original beauty. When properly maintained, cast iron picket fences can last for generations, making them a worthy long-term investment.

You can also find combinations of window designs, such as opening outward windows combined with a tilt-and-turn. Of course, it’s also possible to integrate all these types of aluminium windows within a door screen.

Optional pricing for powdered-coated or painted panels

Cutting

In summary, a stainless steel box with a lock delivers a combination of durability, security, versatility, and aesthetic appeal, making it an ideal choice for anyone in need of a reliable storage solution. Whether you are looking to secure sensitive documents, store valuable items, or simply keep your workspace organized, investing in a stainless steel box can provide you with confidence and peace of mind. As security and organization continue to be important priorities in our lives, embracing such a practical and efficient storage solution is more relevant than ever.